How Constant Light Works

|

How Constant Light Works |

|

|

Constant Light control is a method of automating the operation of the system’s lamps. Its use can provide a great deal of convenience for the building’s occupants, but perhaps the main reason for using it is that it provides a considerable increase in energy efficiency. It ensures that the output of the lamps is no higher than is required to maintain the desired light level.

For buildings fitted with air conditioning systems, there is an additional saving associated with reducing the need to remove waste heat.

|

The effect of this is that the lamps should only output sufficient light to maintain the desired level of light in the room. This means that the lamps will be operating at a low level, or will be switched off, when the room is filled with sunlight. The lamp’s output will gradually increase as night falls, or the sky becomes overcast. Since the lamps will only provide the amount of light that is necessary, they will use the absolute minimum amount of energy, in order to achieve the desired light level. |

The art of designing a successful Constant Light control system is to position the sensor carefully and to set the target levels within the capabilities of the lighting system.

Do not have the Multisensor too close to the window.

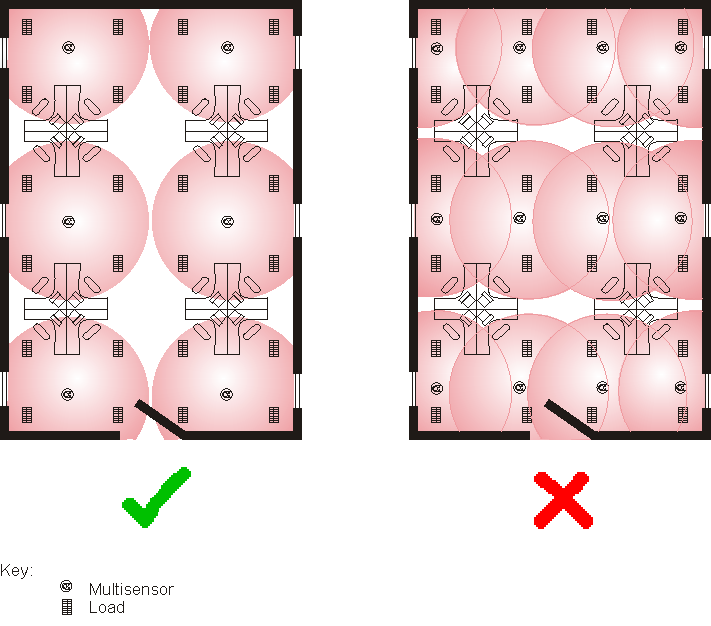

Ensure that the Multisensors are positioned so that their viewing angles do not overlap. For information about Light Sensor viewing angles, see Light Sensor.

Ensure that the Multisensor is situated in the vicinity of the loads that you want Constant Light control to affect, and not near another Multisensor, or lights that are being monitored by another Multisensor (Light Sensor).

There are three important factors to be aware of:

The amount of light that the sensor receives is highly dependent on the reflective qualities and colour of the surfaces in its viewing area. The sensor is very sensitive and if the qualities of the surface it is viewing change, the Multisensor will respond by adjusting the light output accordingly.

For instance, if the sensor is set up over a desk made of a dark material, placing white paper documents on the desk top will increase the reflected light by a considerable amount. The sensor will 'see' this as evidence of a brighter room, and will dim the lamps accordingly. If the paper is removed, the sensor will receive less light, and the lamps will brighten. A similar effect can occur if furnishings of the room are rearranged after the light sensor has been set up.

The design of the system provides a partial answer to this in that its response to changes in light level is very slow. This means that the room's occupants will not see an annoying fluctuation of light as the reflectivity of the sensing area changes. You can also minimise the effect by ensuring that the Multisensor is installed in a location that is not going to be subject to routine changes of reflectivity in its viewing area. Also, ensure that it is not positioned too close to the window, as this will affect the overall light level that the sensor measures.

The Light Sensor's viewing angle restrictor should normally be used to help with this. See Light Sensor.

The Constant Light process functions on a simple feedback principle, and has no means of knowing the capabilities of the lamps that it is controlling. This means that it is possible to set the target level so that the system will attempt to make the lamps produce more light than they are capable of.

If the target level is set on a bright day, the level recorded by the light sensor may be many times the level that the lamps are capable of producing, in the absence of natural light. Under these circumstances the system will simply increase the lamps output to 100% and will remain operating at that level.

The solution to this is to set up the target levels with the blinds drawn, on a dull day, or at dusk. The aim is to ensure that the majority of light that the sensor is receiving is produced by the lamps under Constant Light control. If the system's users are to have control of the target level, it is important to make them aware of this.

The light level measured by the light sensor is relative, and can not be calibrated to correspond to a specific LUX level produced by the lighting system.

However, if attaining specific LUX levels is a requirement of your installation, you can obtain an approximate setting as follows:

Place a LUX meter in the working plane within the Multisensor's viewing area.

Adjust the lamps until the LUX meter shows the desired value.

Store the current multisensor light reading level as a Constant Light target level.

Note:

|

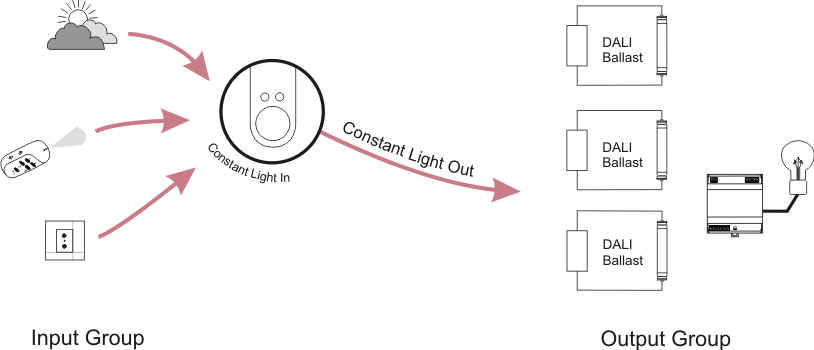

Constant Light operation in router systems may require the use of two groups. The first of these, known as the Input Group (Constant Light Sensor), contains the controllers that are to be used to set up and control constant light operation. The second, the Output Group (Controlled Loads), contains the LIUs (Lamp Interface Units, or loads) for the lamps that are to be subject to constant light control.

Tip:

|

Recall of a Constant Light scene in the Input Group results in that scene being called in the Output Group, and the target level for that Constant Light scene being used. After a settling period, the lights in the Output Group are automatically adjusted to maintain the measured light level at the target level.